Styrene is an important liquid chemical raw material. It is a monocyclic aromatic hydrocarbon with alkene side chain and formed conjugate system with benzene ring. It is the simplest and most important member of unsaturated aromatic hydrocarbons. Styrene is widely used as a raw material for the production of synthetic resins and rubber.

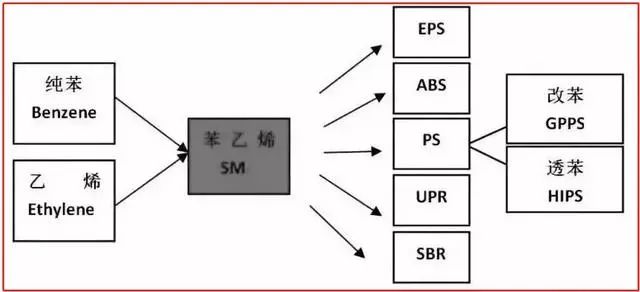

Styrene is an important liquid chemical raw material, belonging to a monocyclic aromatic hydrocarbon with alkene side chain and forming a conjugated system with benzene ring. It is an unsaturated aromatic hydrocarbon styrene “bearing oil coal and connecting rubber and plastic”, and it is an important basic organic raw material for petrochemical industry. The direct upstream of styrene is benzene and ethylene, and the downstream is relatively scattered. The main products involved are foaming polystyrene, polystyrene, ABS resin, synthetic rubber, unsaturated polyester resin and styrene copolymers, and the terminal is mainly used in plastic and synthetic rubber products.

2010 world styrene production capacity expansion, sharply when the increase of about 2.78 million tons of production capacity, productivity growth is close to 10%, mainly is the world especially in China to the downstream products of styrene (terminal used in household appliances, automobile and building materials industries) consumption, which in 2009 and 2010, China’s demand for styrene were above 15%. After 2010, the growth rate of global styrene production capacity gradually slowed down, and by the end of 2017, global styrene production capacity reached 33.724 million tons.

The world’s styrene production capacity is mainly concentrated in East Asia, North America and Western Europe, which account for 78.9% of the world’s styrene production capacity. In addition, the Asia-Pacific region accounts for 52 percent of the world’s styrene production capacity.

The downstream demand for styrene is relatively dispersed, and the end products are mainly plastic products and synthetic rubber.

From the global downstream demand of styrene in 2016, 37.8% styrene is applied to polystyrene, 22.1% to foaming polystyrene, 15.9% to ABS resin, 9.9% to styrene butadiene rubber, 4.8% to unsaturated resin, etc.

With the increase of new domestic production capacity, China’s styrene import volume and import dependence have declined steadily in recent years.

According to customs data, in 2018, China’s major styrene import countries are Saudi Arabia, Japan, South Korea, Singapore, etc. Before 2017, the major sources of styrene imports were South Korea, Saudi Arabia and the United States, with South Korea being the largest source of imports.

Since June 23, 2018, the Ministry of Commerce of China has imposed anti-dumping duties ranging from 3.8% to 55.7% on styrene imported from the Republic of Korea and the United States for a period of five years, resulting in a significant decrease in the proportion of China’s imports from the Republic of Korea in the second half of 2018, with Saudi Arabia and Japan becoming the main source countries of imports.

With the intensive production of domestic private refineries, a large number of new production capacity of styrene will be put into operation in China in the future.

During the “13th Five-Year Plan” period, China orderly promoted domestic private refining and petrochemical integration projects. At present, Hengli, Sheng and other ten million level refining and petrochemical integration projects have been approved to enter the construction peak period, and most large refining and petrochemical enterprises support downstream styrene devices.

Post time: Sep-19-2022